Enter the ESFR fire sprinkler.

Designed specifically for challenging storage environments, the ESFR (Early Suppression Fast Response) system has revolutionized warehouse fire protection. But what is an ESFR fire sprinkler, and how does it differ from standard models? As a leading , Hengdun Firefighting breaks down the technology, benefits, and specifications you need to know.

What is an ESFR Fire Sprinkler System?

ESFR stands for Early Suppression, Fast Response. It is a type of ceiling-mounted fire sprinkler designed to handle high-challenge fire hazards without the need for additional in-rack sprinklers.

Unlike conventional sprinklers, ESFR heads are engineered with two critical characteristics:

-

Fast Response: They use a highly sensitive thermal element (often a ) with a low Response Time Index (RTI), allowing them to activate much faster than standard sprinklers during the initial stages of a fire.

-

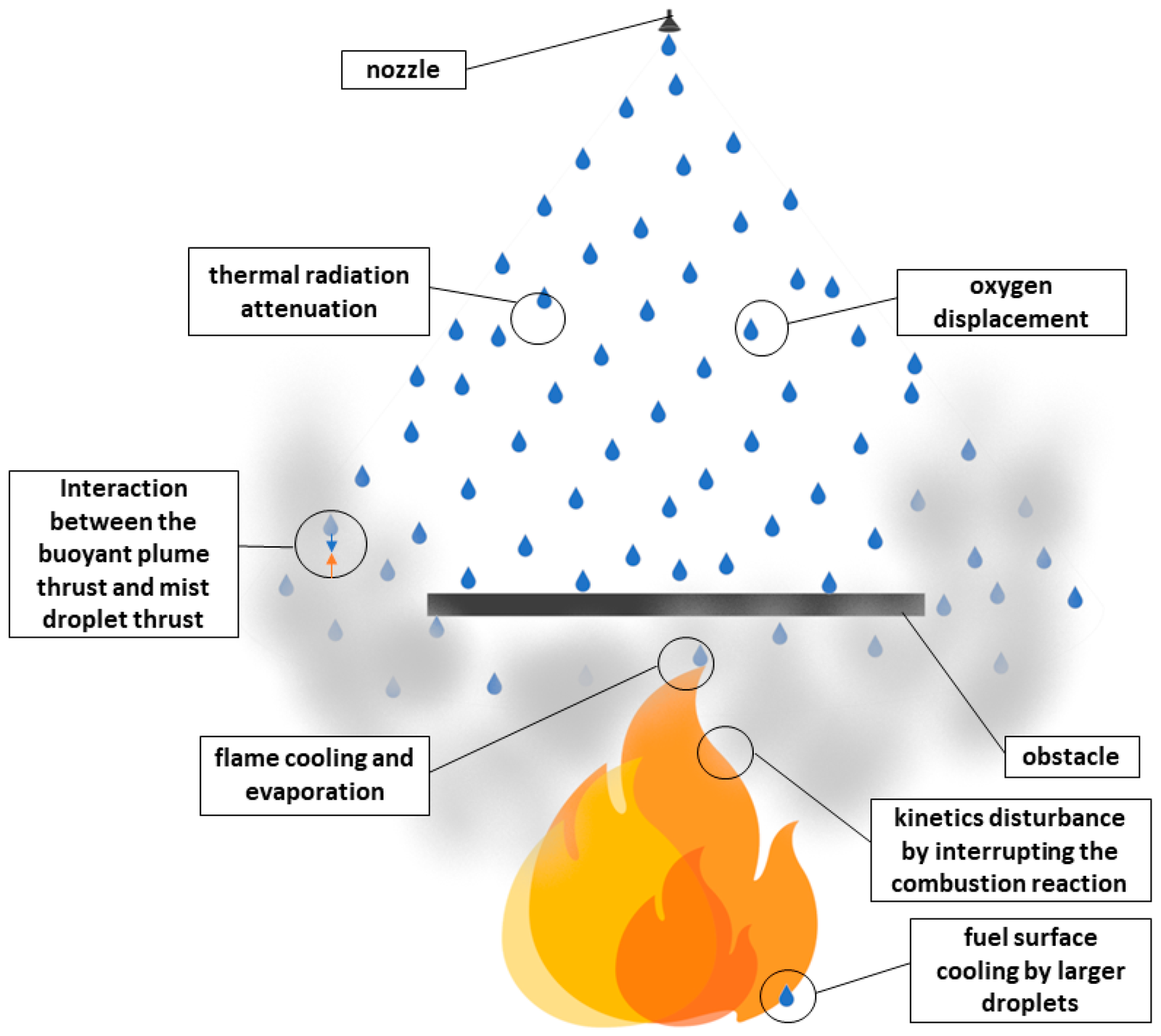

High Volume & Velocity: They discharge a large volume of water at high momentum. This produces heavy water droplets capable of penetrating the rising hot air (fire plume) to reach the burning fuel source directly.

ESFR vs. Standard Spray Sprinklers: The Big Difference

To understand the value of an , you must understand the difference between “Fire Control” and “Fire Suppression.”

Standard Sprinklers = Fire Control

Standard spray sprinklers (like standard Pendent or Upright heads) are designed to control a fire. They wet the ceiling and the area surrounding the fire to prevent it from spreading, effectively “containing” the blaze until the fire department arrives to extinguish it.

ESFR Sprinklers = Fire Suppression

ESFR systems are designed to suppress (or extinguish) the fire directly. By dumping a massive amount of water quickly right onto the burning rack, they reduce the heat release rate drastically, often extinguishing the fire before firefighters even reach the scene.

Industry Insight: Because ESFR heads attack the fire source, they require higher water pressure and larger pipe diameters compared to standard systems.

Top Benefits of Installing ESFR in Warehouses

For warehouse owners and logistics managers, choosing an ESFR system offers significant operational and economic advantages.

1. Eliminating In-Rack Sprinklers

This is the primary reason ESFR was invented. Traditional systems for high racks often require “in-rack” sprinklers installed at various levels within the shelving.

-

The Problem with In-Rack: They are expensive to install and prone to damage from forklifts loading and unloading pallets.

-

The ESFR Solution: Being ceiling-mounted, ESFR heads protect the entire vertical height of the rack from above, removing the need for complex in-rack piping.

2. Flexibility for Storage Configuration

In modern logistics, storage needs change rapidly. If you use in-rack sprinklers, rearranging your shelving means ripping out and reinstalling pipes. With a ceiling-mounted using ESFR heads, you can reconfigure your floor layout and rack height without modifying the sprinkler system (as long as you stay within the maximum ceiling height limits).

3. Protection for High-Challenge Commodities

ESFR sprinklers are FM Global and UL listed to protect a wide range of commodities, including plastics (cartoned or uncartoned), paper, and rubber tires, which burn hotter and faster than standard goods.

Technical Specifications: Understanding K-Factors

When selecting an ESFR sprinkler, you will often hear about the “K-Factor.” This represents the discharge coefficient—essentially, how much water flows through the head at a given pressure.

Hengdun Firefighting manufactures a range of ESFR sprinklers to suit different ceiling heights:

-

K14 (K200): The original standard, suitable for ceiling heights up to 12.2m (40 ft).

-

K17 (K242) & K22 (K320): Designed for lower pressure requirements or higher ceilings.

-

K25 (K360): High-performance heads for ceilings up to 13.7m (45 ft) and heavier fire loads.

Note: Always consult NFPA 13 standards and your system designer to choose the correct K-Factor for your building.

Why Source ESFR Sprinklers from Hengdun?

Manufacturing ESFR sprinklers requires precision engineering. The fusible alloy element must melt at the exact rated temperature, and the deflector must create a perfect water pattern.

At , we ensure reliability through:

-

100% Testing: Every batch undergoes rigorous pressure and thermal activation tests.

-

Premium Materials: We use durable brass bodies and high-quality fusible alloys to ensure longevity in industrial environments.

-

Certified Compliance: Our products meet international quality standards (ISO 9001, CCC).

FAQ: Common Questions About ESFR Systems

Can ESFR sprinklers be used on sloped ceilings? Generally, no. ESFR sprinklers are strictly regulated for use on roofs with a slope of less than 9.5 degrees (2 in 12 pitch). Excessive slope can deflect the heat layer away from the sprinkler, delaying activation.

Is a fire pump required for ESFR systems? In most cases, yes. Because ESFR heads require high pressure (often 50-75 PSI at the most remote head) and high water flow, municipal water supplies rarely provide enough pressure without a booster pump.

What is the maximum ceiling height for ESFR? This depends on the K-Factor and the commodity being stored, but generally, the limit is around 13.7m to 14.6m (45-48 ft). For warehouses taller than this, specialized designs or in-rack sprinklers may still be required.

Conclusion

The ESFR fire sprinkler is the gold standard for modern warehouse protection. By combining early suppression capabilities with the elimination of in-rack piping, it offers a safer, more flexible, and cost-effective solution for logistics centers.

Ensure your high-value inventory is protected by the best technology.

Planning a warehouse project?